Get in Touch With Us and Tell Us About Your Toughest Monitoring and Control Challenges.

SignalFire Telemetry products connect you with crucial product and hardware data at any of your oil and gas operation sites—whether it’s a pump, pipeline, or storage tank.

SignalFire Telemetry devices install anywhere water asset monitoring is needed, whether it’s for collection purposes, treatment, or delivery.

SignalFire Telemetry devices can monitor key assets and can do it affordably, without any renovation or high-priced engineering costs. They install easily with no required cable or additional power. The data is available on your phone or computer and the cloud service can even output to your corporate system to integrate with the rest of your data and keep your operation running.

SignalFire Telemetry devices can monitor and manage water supplies and additives throughout the property, helping you avoid catastrophic shortages and keep your irrigation plan on track.

Avoid costly product loss in bulk storage tanks, terminals, and transportation movements. Whether calling for tank levels, gauge pressure, or even movement pumps or pipelines, SignalFire products can fill any monitoring gap throughout a facility.

Environmental fines for businesses are be frustrating and can bring business to a standstill until they’re worked out. No business wants to hurt the environment, and in competitive markets stopping production affects the bottom line and staff. But there are effective and affordable solutions with SignalFire Telemetry devices.

Expand visibility and control of your refinery or petrochemical processing facility without expensive renovations or redesigns. And do it with your current gauges and hardware. SignalFire telemetry devices are designed to work in harsh chemical environments and meet the strictest safety and security standards

No matter the size of your service map, monitoring remote assets ensures efficiency and keeps your operation in compliance. That’s how SignalFire devices can really help, offering the most affordable and effective monitoring solution that will monitor liquid, gas, electricity, and other assets.

Explore the diverse applications of SignalFire Wireless Telemetry Systems across different industries.

Access our latest brochures to explore comprehensive information about our products and services.

Easily find the sensors that are compatible with our systems on this dedicated page.

Explore a comprehensive collection of images showcasing our products, installations, and real-world applications.

Measuring the flow of a fluid or gas is essential to many industrial processes. Many technologies exist to measure flow including Electromagnetic, Ultrasonic, Turbine, Vortex, Positive Displacement, Coriolis, and Thermal Mass flow meters. The ability to monitor the flow rate and flow totals from various flow meters wirelessly enables users to avoid costly conduit runs from the point of the flow measurement back to a central controller.

The most basic output from a flow meter is typically a pulse output. The flow meter will output pulses proportionally to the flow, for example a meter might output 1 pulse per gallon. The pulses per unit volume is commonly referred to the as the meter K-factor. Turbine meters also have a K-factor and typically have a magnetic pickup that outputs a low voltage sine wave.

Next, some more advanced electronic flow meters support digital communications such as HART or Modbus. These protocols allow the host device to read the flow rate and flow total digitally without the chance for any loss of data or mismatch between the flow meter and the attached totalizer device.

Pictured here is a Coriolis Mass flow meter with SignalFire’s RANGER installed to wirelessly send flow data via Modbus to the Cloud.

SignalFire has a variety of products that can easily interface to the common flow meter outputs listed above and bring the

flow meter data wireless to a centrally located gateway using 900MHz wireless transmission, or directly to the Cloud using LTE-M cellular technology.

The SignalFire Wireless Totalizer and the SignalFire RANGER both have digital inputs that can accept a pulse output from a flow meter. They have a configurable K-factor and volume units so the user can view their flow totals and flow rates in the units that make sense for the application.

The SignalFire Sentinel-485 and the SignalFire Modbus Stick may both be used with a flow meter that supports the Modbus protocol. The SignalFire Modbus node will be programmed to pull the flow meter data over the RS485 Modbus connection and forward the readings to the SignalFire Gateway. Additionally, the SignalFire RANGER supports Modbus, allowing Modbus flow meter data to be transmitted directly to the Cloud over LTE-M cellular networks.

Flow meters with a HART interface can be read using the Sentinel-HART, the A2-HART, or the RANGER. The HART data will be read from the meter and forwarded to the SignalFire Gateway or SignalFire Cloud. The SignalFire Modbus/HART devices also allow the user to wirelessly send data to the flow meter allowing configuration and diagnostics of the flow meter to happen remotely without a visit to the site.

Adding wireless to a flow meter to bring the data to a central point or directly to the cloud can be easily accomplished using a variety of SignalFire devices, depending on your specific flow meter type and network requirements. The SignalFire system also allows other measurements including pressures, temperatures, and tank levels to be conveniently monitored, further expanding the flexibility of the system.

Please contact SignalFire to discuss your specific measurement needs.

Ultrasonic flow meters provide flow measurement readings without interfering with the fluid flowing through the pipe, so there is no pressure drop.

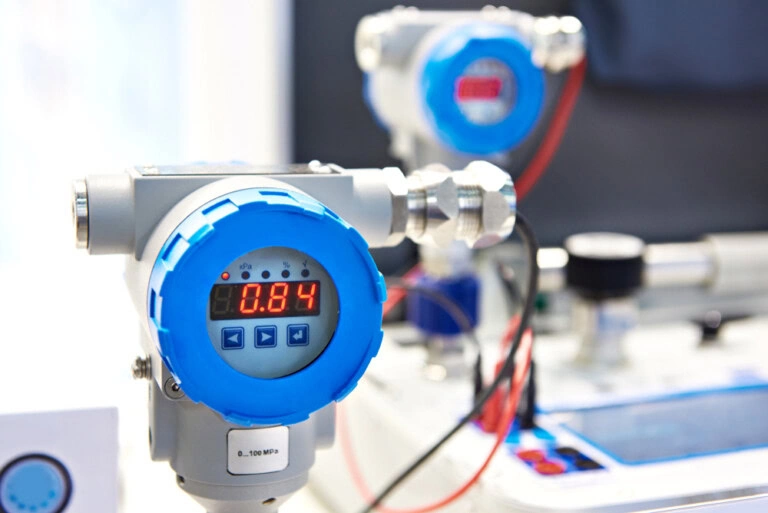

There are several types of Electromagnetic flow meters (“Magmeters”) on the market. Pictured here are an Inline Magmeter (left) and Insertion Magmeter (right).

Mechanical flow meters like Positive Displacement (left) and Turbine (right) are commonly used to measure clean, non-abrasive, non-viscous liquids.

Industrial Thermal Mass flow meters are ideal for natural gas and air flow measurement.

Get in Touch With Us and Tell Us About Your Toughest Monitoring and Control Challenges.

"*" indicates required fields

This website uses cookies so that we can provide you with the best user experience possible. Cookie information is stored in your browser and performs functions such as recognising you when you return to our website and helping our team to understand which sections of the website you find most interesting and useful.

Strictly Necessary Cookie should be enabled at all times so that we can save your preferences for cookie settings.

If you disable this cookie, we will not be able to save your preferences. This means that every time you visit this website you will need to enable or disable cookies again.