Get in Touch With Us and Tell Us About Your Toughest Monitoring and Control Challenges.

SignalFire Telemetry products connect you with crucial product and hardware data at any of your oil and gas operation sites—whether it’s a pump, pipeline, or storage tank.

SignalFire Telemetry devices install anywhere water asset monitoring is needed, whether it’s for collection purposes, treatment, or delivery.

SignalFire Telemetry devices can monitor key assets and can do it affordably, without any renovation or high-priced engineering costs. They install easily with no required cable or additional power. The data is available on your phone or computer and the cloud service can even output to your corporate system to integrate with the rest of your data and keep your operation running.

SignalFire Telemetry devices can monitor and manage water supplies and additives throughout the property, helping you avoid catastrophic shortages and keep your irrigation plan on track.

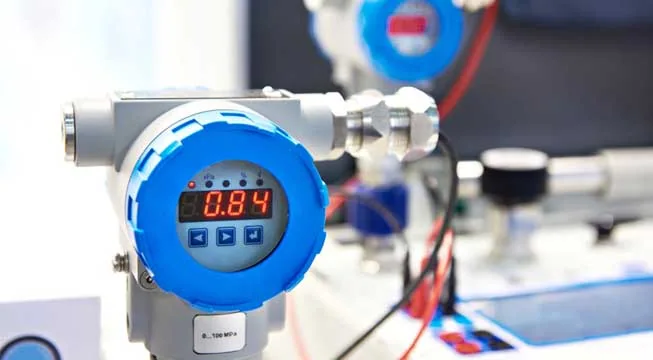

Avoid costly product loss in bulk storage tanks, terminals, and transportation movements. Whether calling for tank levels, gauge pressure, or even movement pumps or pipelines, SignalFire products can fill any monitoring gap throughout a facility.

Environmental fines for businesses are frustrating and can bring business to a standstill until they’re worked out. No business wants to hurt the environment, and in competitive markets stopping production affects the bottom line and staff. But there are effective and affordable solutions with SignalFire Telemetry devices.

Expand visibility and control of your refinery or petrochemical processing facility without expensive renovations or redesigns. And do it with your current gauges and hardware. SignalFire telemetry devices are designed to work in harsh chemical environments and meet the strictest safety and security standards

No matter the size of your service map, monitoring remote assets ensures efficiency and keeps your operation in compliance. That’s how SignalFire devices can really help, offering the most affordable and effective monitoring solution that will monitor liquid, gas, electricity, and other assets.

Explore the diverse applications of SignalFire Wireless Telemetry Systems across different industries.

Access our latest brochures to explore comprehensive information about our products and services.

Easily find the sensors that are compatible with our systems on this dedicated page.

Explore a comprehensive collection of images showcasing our products, installations, and real-world applications.

Many monitoring applications require different sensor types to measure and report various parameters to a central Gateway, programmable logic controller (PLC), or other control device. For instance, in the upstream oil and gas market, level, temperature, pressure, flow and other points are monitored in different applications. Sensor choice is often driven by the environment, desired accuracy, cost and what is being monitoring. In tank level monitoring, for example, the contained materials as well as monitoring requirements dictate the best sensing technology for the job.

It is rare that an operator will want to use sensors for all required measurements from a single sensor manufacturer. In fact, a single manufacturer rarely supplies all these different types of sensors.

Consequently, the network connecting all these sensors together will need to interface with a variety of sensor types with various sensor interfaces. Common sensor interfaces are 4-20mA, 1-5 Volt, Modbus, HART, digital, pulse and SDI-12. Others exist as well. Wireless connectivity, if used correctly, will solve the issue of mixing multiple sensor interface types and allow all the different data formats to work with each other.

If you are looking for a wireless system that can connect all these different sensor types with different interfaces together, ensure that the wireless vendor has nodes that support different interface types. This allows you to choose the sensor that best solves your application problem and not be handcuffed to buy all your sensors from a single manufacturer and use their wireless system.

To sum up, sensor networks will often utilize different sensor types from different sensor manufacturers. Wireless connection can actually solve the connection problem and allow various sensor interfaces to coexist within the same network by supplying nodes with different sensor interfaces.

SignalFire, for example, can connect to any of the above-mentioned sensor interface types, with all data sent to the Gateway in a common format – Modbus. Unlike most tank level monitoring systems that limit sensor choice, the Signal Fire Remote Sensing System integrates an open architecture mesh network that allows users to choose the preferred sensor type for an application as well as mix sensor types in the same network. This capability provides the freedom to choose the best sensor for each type of measurement point.

For more information on the SignalFire Sensor Interfaces, visit https://www.signal-fire.com/resources/commonly-supported-sensors/.

Download the article on Justifying the Move to Wireless Tank Level Monitoring at: http://www.flowcontrolnetwork.com/justifying-the-move-to-wireless-tank-level-monitoring/ .

Get in Touch With Us and Tell Us About Your Toughest Monitoring and Control Challenges.

"*" indicates required fields