Get in Touch With Us and Tell Us About Your Toughest Monitoring and Control Challenges.

SignalFire Telemetry products connect you with crucial product and hardware data at any of your oil and gas operation sites—whether it’s a pump, pipeline, or storage tank.

SignalFire Telemetry devices install anywhere water asset monitoring is needed, whether it’s for collection purposes, treatment, or delivery.

SignalFire Telemetry devices can monitor key assets and can do it affordably, without any renovation or high-priced engineering costs. They install easily with no required cable or additional power. The data is available on your phone or computer and the cloud service can even output to your corporate system to integrate with the rest of your data and keep your operation running.

SignalFire Telemetry devices can monitor and manage water supplies and additives throughout the property, helping you avoid catastrophic shortages and keep your irrigation plan on track.

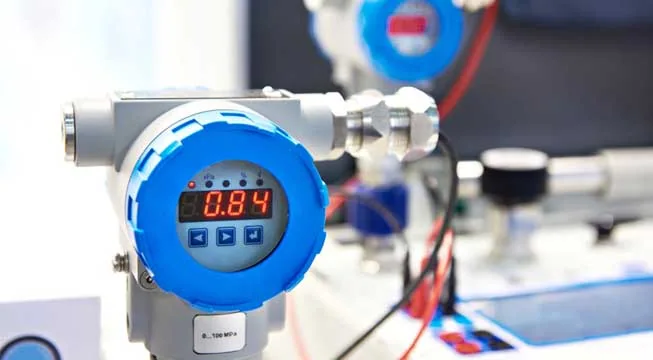

Avoid costly product loss in bulk storage tanks, terminals, and transportation movements. Whether calling for tank levels, gauge pressure, or even movement pumps or pipelines, SignalFire products can fill any monitoring gap throughout a facility.

Environmental fines for businesses are frustrating and can bring business to a standstill until they’re worked out. No business wants to hurt the environment, and in competitive markets stopping production affects the bottom line and staff. But there are effective and affordable solutions with SignalFire Telemetry devices.

Expand visibility and control of your refinery or petrochemical processing facility without expensive renovations or redesigns. And do it with your current gauges and hardware. SignalFire telemetry devices are designed to work in harsh chemical environments and meet the strictest safety and security standards

No matter the size of your service map, monitoring remote assets ensures efficiency and keeps your operation in compliance. That’s how SignalFire devices can really help, offering the most affordable and effective monitoring solution that will monitor liquid, gas, electricity, and other assets.

Explore the diverse applications of SignalFire Wireless Telemetry Systems across different industries.

Access our latest brochures to explore comprehensive information about our products and services.

Easily find the sensors that are compatible with our systems on this dedicated page.

Explore a comprehensive collection of images showcasing our products, installations, and real-world applications.

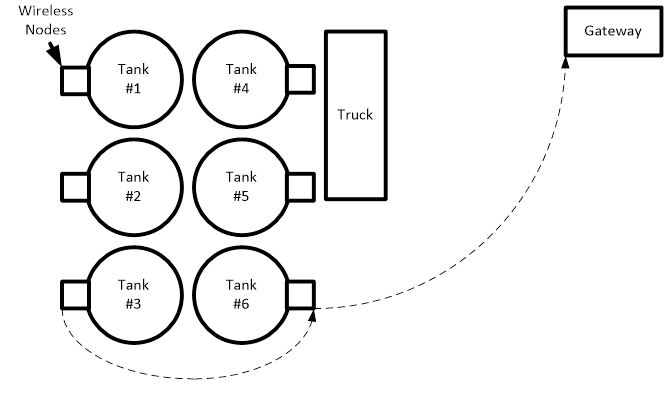

Quite a few sensor radio protocols exist for wireless systems in the SCADA market. A mesh network system is a less commonly known one.

A mesh network allows wireless nodes to utilize neighboring nodes to relay or “hop” messages to a central location (Gateway). Each node determines the “best path” to the Gateway based on information derived from nearby nodes. The intuitiveness of the nodes allows the system to automatically adjust to changes so data can take alternative paths when necessary to its ultimate destination.

The self-configuring capability of the mesh network proved essential in the following tank level monitoring application that required frequent network changes.

In the original configuration of a mesh network supporting the wireless remote monitoring and control of tank levels, eight short-range wireless nodes measured tank levels, checking into a Gateway about 1000 feet away. Hydrostatic pressure sensors, monitoring the tank level, as well as the wireless nodes, were installed at ground level. Four of the nodes were on the “wrong” side of the tank battery and had to transmit “through” the tanks to get data to the Gateway. This configuration worked fine until a tanker truck parked between the tanks and the Gateway. With the tanker in the way, one or two or the nodes on the far side of the tank battery could not directly reach the Gateway.

The problem was solved by solar powering one of the nodes on the near side of the tank battery, allowing it to automatically forward messages, if necessary. When the truck was not present, all nodes would check into the Gateway directly. When the truck came to offload oil and blocked some of the nodes on the backside of the tank battery, those nodes would automatically reroute their message path through the always-on node on the front. Once the truck drove away, those nodes reverted to direct communications with the Gateway.

Without the mesh networking capability, the wireless remote monitoring and control system would not work under varying circumstances. No configuration or setup is needed with a true mesh system as it operates automatically, freeing the installer of complicated RF worries.

Read more about SignalFire’s unique two-way mesh technology by clicking at here. For an overview of the SignalFire Remote Sensing System that utilizes mesh networking technology, download our video by clicking here .

Get in Touch With Us and Tell Us About Your Toughest Monitoring and Control Challenges.

"*" indicates required fields